Comprehending the Relevance of Aluminum Casting in Modern Production Processes

Light weight aluminum casting has arised as a vital part in contemporary manufacturing. Its sturdy and light-weight nature adds substantially to various markets, from automobile to electronics. In addition, improvements in casting methods boost manufacturing efficiency and top quality. As suppliers look for innovative solutions, the role of aluminum casting in sustainability ends up being progressively important. This discussion will discover the diverse significance of light weight aluminum spreading and its implications for the future of manufacturing. What lies ahead in this progressing landscape?

The Advantages of Light Weight Aluminum Spreading in Manufacturing

Aluminum casting deals various advantages that boost its appeal in modern-day manufacturing procedures. One major benefit is its lightweight nature, which brings about decreased power consumption and improved gas performance in transportation applications. Furthermore, light weight aluminum's exceptional corrosion resistance extends the lifespan of actors products, making them a lot more durable in numerous settings. The product likewise promotes complicated geometries and detailed designs, enabling suppliers to develop components that meet exact specifications.

Additionally, aluminum spreading flaunts a reasonably low melting point, which saves power during the manufacturing procedure. This quality additionally enables fast cycle times, raising general productivity. Furthermore, the recyclability of light weight aluminum adds to sustainability efforts, as recycled light weight aluminum requires substantially much less energy to procedure compared to key aluminum. Jointly, these benefits setting aluminum spreading as a crucial method in modern manufacturing, dealing with the needs for efficiency, efficiency, and ecological responsibility.

Applications of Light Weight Aluminum Spreading Throughout Industries

While various products are employed in production, aluminum casting has come to be a critical approach across several sectors because of its versatility and functionality. This process is widely made use of in the auto market for creating lightweight engine blocks, transmission cases, and numerous parts that enhance fuel performance. In the aerospace sector, aluminum spreading is important for creating intricate components that call for high strength-to-weight ratios, adding to improved airplane performance.

The electronics sector depends on light weight aluminum castings for warmth sinks and real estates, where thermal administration is crucial for device durability. The building and construction sector additionally takes advantage of light weight aluminum spreading in the form of building parts and structural aspects that incorporate aesthetic charm with sturdiness. Furthermore, the durable goods market uses aluminum castings for cookware and sporting equipment, leveraging the product's superb rust resistance and aesthetic coating. In general, light weight aluminum spreading functions as a cornerstone in modern-day manufacturing, sustaining varied applications throughout various fields.

The Function of Aluminum Casting in Sustainability

Sustainability has actually become a focal point in manufacturing techniques, and aluminum casting plays an important duty in advertising environmentally friendly remedies. The process of light weight aluminum spreading is naturally lasting due to the product's recyclability. Light weight aluminum can be reused numerous times without shedding its homes, greatly decreasing energy consumption and raw material requirements. This recycling process takes in only around 5% of the power needed for primary aluminum manufacturing, leading to a notable decrease in carbon exhausts.

Moreover, light weight aluminum casting assists in the production of light-weight components, which add to power efficiency in different applications, specifically in the aerospace and automobile fields. Lighter vehicles eat much less gas, additional lessening environmental influence. Furthermore, developments in casting techniques are enhancing product application, lowering waste in making procedures. As markets seek to straighten with sustainability goals, aluminum casting arises as a sensible remedy, sustaining a circular economic situation and fostering responsible production techniques

Technological Developments in Aluminum Spreading Techniques

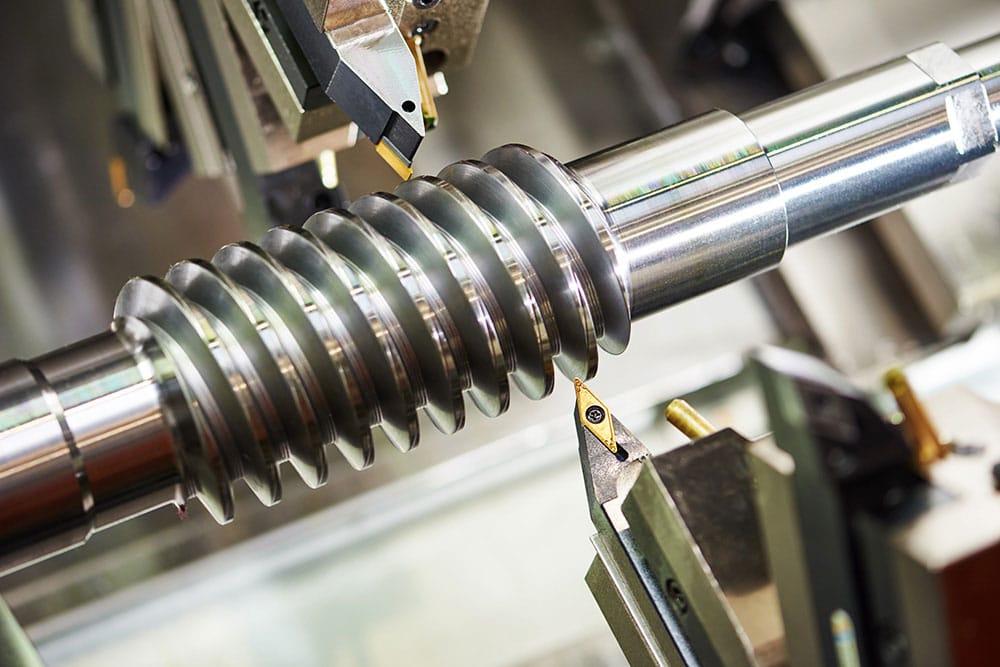

As sectors progress, the adoption of ingenious modern technologies in aluminum casting techniques has actually changed making procedures. The integration of computer-aided style (CAD) and computer-aided production (CAMERA) systems enhances precision and performance, permitting for intricate geometries that were formerly challenging to create. Advanced melting and casting approaches, such as die casting and financial investment spreading, have enhanced the top quality of light weight aluminum parts, decreasing issues and minimizing waste. The intro of automated systems and robotics in casting procedures has streamlined operations and increased efficiency. These advancements also allow real-time surveillance and information analytics, helping with much better decision-making and quality assurance. In addition, the development of new alloys and heat therapy processes has actually broadened the performance capacities of actors light weight aluminum items. Collectively, these technological advancements not only optimize manufacturing performance yet additionally contribute to the sustainability of aluminum spreading in modern production.

Future Trends in Aluminum Spreading and Its Influence On Development

Emerging fads in aluminum spreading are poised to improve the manufacturing landscape, driving advancement across various sectors. One significant trend is the integration of innovative automation and robotics, which improves precision and efficiency in manufacturing procedures. In addition, the rise of additive production techniques is enabling a lot more complex designs, reducing material waste and manufacturing time. As sustainability comes to be a concern, the industry's focus on reusing aluminum and making use of environment-friendly methods is anticipated to expand, aligning with international ecological goals.

Furthermore, the growth of wise casting technologies, consisting of real-time tracking and data analytics, is set to enhance quality assurance and functional effectiveness. These improvements will facilitate the production of lighter, more powerful, and much more resilient aluminum components, satisfying sectors such as auto and aerospace. Inevitably, these patterns will not just enhance manufacturing processes but also motivate brand-new applications of aluminum spreading, cultivating a society of technology and adaptability on the market.

Frequently Asked Inquiries

What Is the History of Light Weight Aluminum Casting in Manufacturing?

Exactly How Does Light Weight Aluminum Casting Contrast to Various Other Steels?

Aluminum casting offers advantages such as lightweight properties and rust resistance contrasted to various other metals. aluminum casting. It boosts and promotes intricate forms energy performance, making it a preferred choice in different manufacturing applications over much heavier alternatives like steel or iron

What Are the Common Problems in Light Weight Aluminum Spreading?

Common problems in aluminum spreading consist of porosity, shrinkage, misruns, and inclusions. These issues can develop from incorrect pouring techniques, inadequate mold and mildew layout, or contaminated products, leading to reduced structural honesty and efficiency of the final product.

How Is the Top Quality of Light Weight Aluminum Castings Tested?

The high quality of light weight aluminum castings is tested through approaches such as visual assessments, dimensional dimensions, non-destructive testing strategies, and mechanical home evaluations, making sure that they fulfill specified standards for performance and architectural honesty.

What Are the Safety Actions in Light Weight Aluminum Spreading Processes?

Security measures in light weight aluminum casting procedures include using individual protective tools, correct air flow systems, routine devices upkeep, training workers on dangers, and executing stringent emergency methods to lessen threats related to heats and molten steel.

The recyclability of light weight aluminum adds to sustainability efforts, as recycled aluminum calls for considerably less power to procedure compared to key aluminum. While numerous products read more are used in manufacturing, light weight aluminum casting has actually become an essential method across numerous industries due to its flexibility and capability. Advanced melting and spreading methods, such as die casting and financial investment casting, have boosted the top quality of light weight aluminum parts, reducing and minimizing defects waste. Emerging trends in aluminum casting are poised to improve the production landscape, driving innovation across numerous sectors. Light weight aluminum spreading has evolved given that the late 19th century, initially establishing with the introduction of aluminum as a light-weight metal.